Each Industrial Water Cycle has its own characteristics. To be able to obtain the highest efficiency and performance form the system, the equipment and chemicals that are used in the water management system must be customized. This is where TEKKON Petrochemical Services Co. Ltd. hopes to make a difference.

TEKKON Petrochemical Services Co. Ltd. provides a wide range of water management chemicals used in every aspect of the Industrial Water Cycle. The Industrial Water Treatment product range is constantly evolving with new products formulated following the latest developments in the sector.

The unique characteristics of each Industrial Water Cycle makes optimization of services and products necessary. TEKKON Petrochemical Services Co. Ltd. provides customized production chemicals and/or customizes the most effective product in its product range for maximum efficiency.

RAW WATER TREATMENT

- ANTISCALANTS

- FLOCCULANTS

- ORGANIC and INORGANIC COAGULANTS

- ANIONIC AND NONIONIC POLYACRYLAMIDE

- CATIONIC POLYACRYLAMIDE

- DEFOAMERS

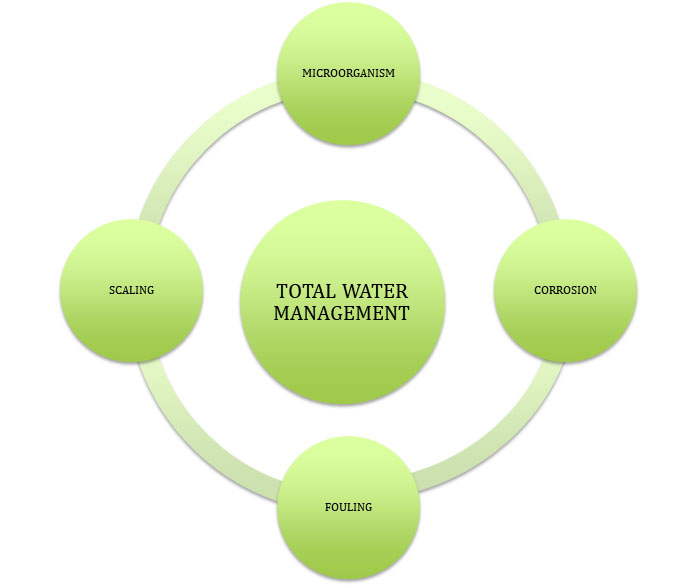

COOLING SYSTEM WATER MANAGEMENT

PRE-TREATMENT: Raw water accommodates unwanted colloids, suspended solids and microorganisms that will affect cooling system operations. Therefore pre-treatment is crucial for successful cooling water treatment. Tekkon Petrochemical Services Co. Ltd. Offers chemicals for excellent water quality:

- Coagulants

- Flocculants

- Dysenfectants

MICROBIOLOJICAL CONTROL: Process leaks, typical containments will result in bacteria, fungi and algae, which will create fouling. Tekkon Petrochemical Services Co. Ltd. Offers a wide variety of customized chemicals to control fouling:

- Oxidizing Biocides

- Non-Oxidizing Biocides

Water is where life starts and grows; it is very difficult reach zero quantity of bacteria in water systems.

The only right way is to control bacteria levels within limitations to avoid algae and slime forming.

Continuous disinfection with oxidising biocides is an alternative but may enhance corrosion within systems.

The right selection of treatment products, raw water quality and continuous control is the right way to success of treatment.

SCALE, CORROSION AND FOULING CONTROL: Custom tested and formulated products which are developed for efficient performance of our clients:

- Oxygen Scavengers

- Scale Inhibitors

- Corrosion Inhibitors

- Filming Amines

- Emulsion Breakers

- Antiscalants

- Dispersants

All cooling and heating systems that are running on water; are under threat of corrosion. According to Ryznar index of raw water quality and circulation parameters, corrosion occurs in several types;

- Erosion

- Oxygen

- Pitting

- Under Deposit

- Stress

- Galvanic

- Planiform

Scale:

Raw water from nature (Ground and/or Surface) contains dissolved solids that can easily precipitate due to system conditions such as heat, concentration, pressure, flow etc.

This scaling is forming due to carbonates of divalent salts. To avoid scaling, hardness stabilizers are used for treatment.

FOULING

As water contains dissolved solids, it contains none dissolved (suspended) solids and bacteria, which can cause fouling (sedimentation) of such impurities.

Suspended solids are coming from contamination of water systems, raw water quality and pure pre-treatment of water.

Water is always having bacteria and water systems are very convenient for growth due to heat, dissolved gases, light.

Both organic (bacteria) growth & formation of slime and sedimentation of suspended solids cause fouling inside of the systems.

WASTE WATER TREATMENT

- Flocculants

- Defoamers

- Emulsion Breakers

Polymers

SUPPLY OF COMMODITY WATER TREATMENT CHEMICALS

- Chlorine Gas

- CHC

- Ferric Chloride (FeCl3)

- Aluminium Sulphate ( Al2 (SO4)3

- Sodium Hypochloride (NaClO)

- Sodiummetabisulfite (Na2S2O5)

- Sodium Chloride (NaCl)

- Citric Acid

- Sodium EDTA