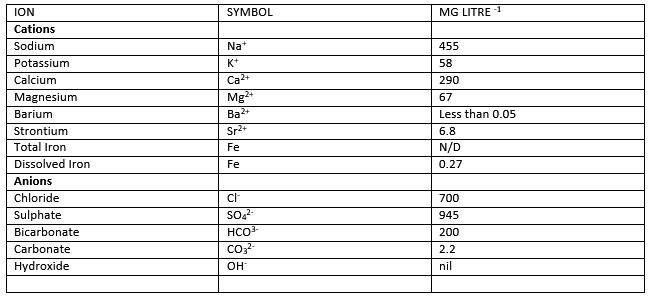

Produced Water Chemistry Data :

SCOPE OF WORK

One scale inhibitor, Oil Guard XX, is proposed for application to the produced water system downstream of process separation and upstream and downstream of the produced water tanks and strippers. Here the fluids are more benign, but still contain ions likely to contribute to the deposition of inorganic scales such as carbonate and sulphate.

Scope of work as follows:

- Determination of blank scaling time at system temperature and ionic concentration using the water chemistry provided.

- Chemical screening of scale inhibitor once blank time is established in a coarse test and a fine test.

- An estimate the Minimum Inhibitory Concentration (MIC) of the chemicals in laboratory simulated conditions.

DYNAMIC SCALE LOOP TESTS

DETERMİNATION OF BLANK SCALING TIME

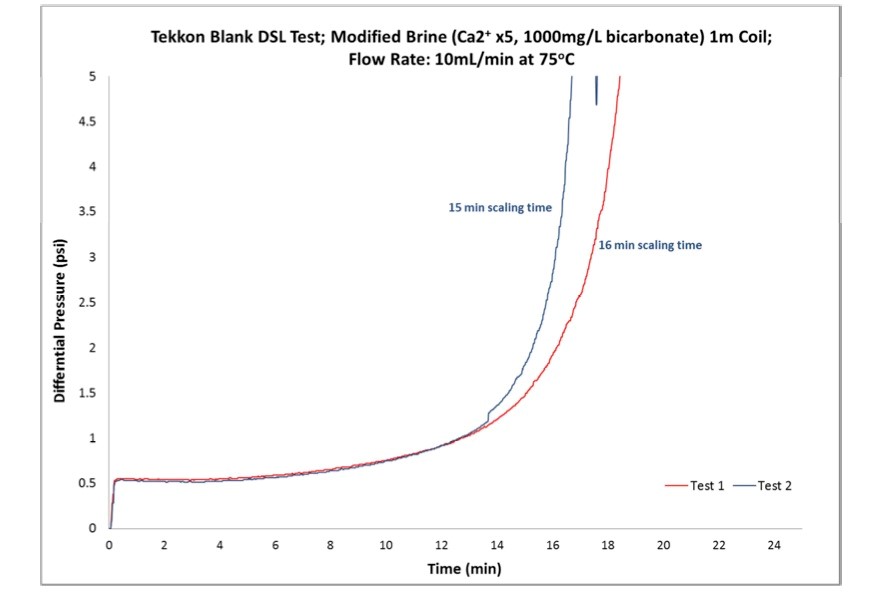

A scaling time is defined as a 1 psi increase in differential pressure under chosen test conditions.

Initial runs were carried out using synthetic brines based on the water chemistry submitted at 54 0C. However, under these conditions no scaling occured in a 1m blocking coil after several hours. The flow rate and then the blocking coil length were increased in a systematic approach to verify whether water chemistry was severe enough to scale at the specified test temperature. However, no scale was formed.

Modifications to the bicarbonate, calcium and temperature of the brine were then modified in order to establish a blank time less than 1 hour as test duration of longer than 1 hour makes laboratory evaluations impractical.

To begin the bicarbonate anions was increased to 5x and in both standard and higher flow rates this did not block the test coil in less than 1 hour test duration. Amendment to the calcium level was then considered and as a result the calcium (Ca2+) concentration was increased 5x. Tests were carried out at 75oC with an effective scale forming with a blank scaling time of approximately 15 and 16 minutes. Consequently a blank scaling time of 18 minutes was established fort he screening test of the scale inhibitor.

CHEMICAL SCREENING OF SCALE INHIBITOR

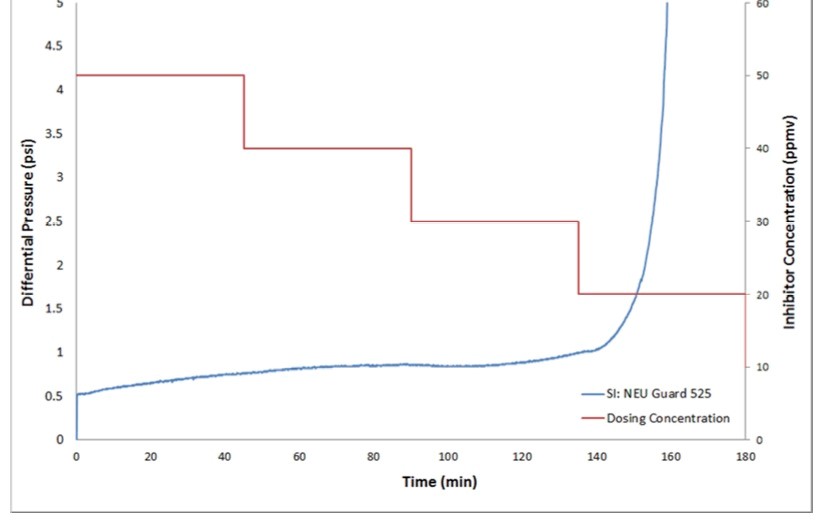

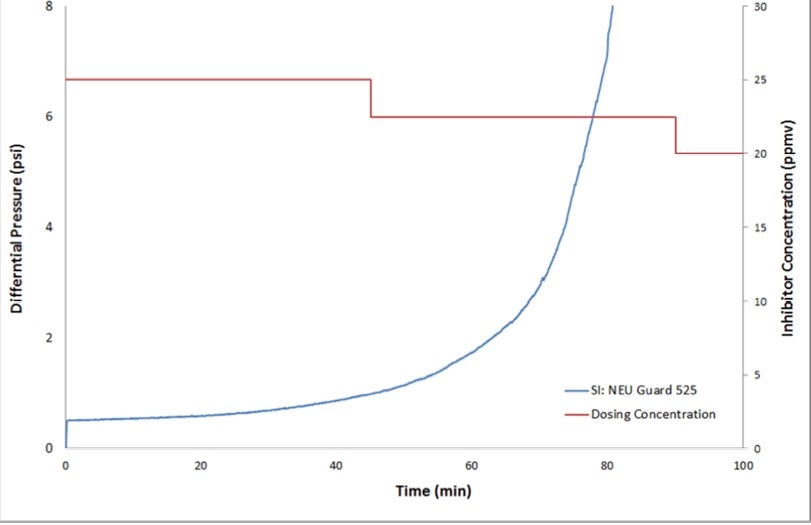

After the blank time was determined, tests were conducted in amended brines on the chemical. An initial coarse run, stepping down in 10 ppm increments, followed by a fine run stepping down from 25ppm in 2.5 ppm increments were carried out to determine the inhibitor concentration required to control the scaling.

The initial coarse run with Oil Guard XX, from 50ppm dropping down to 20 ppm, gave an inhibitory concentration of 30 ppm;

The fine run, from 25 ppm dropping down to 20 ppm in 2.5 ppm steps gave an inhibitory concentration of 25 ppm.

It can be concluded from the above chemical screening assessments that, under the laboratory conditions the Oil Guard XX provides inhibition of experimentally produced carbnate scale at 25ppm.