TEKKON PETROCHEMICAL SERVICES CO. LTD.

CLIENT2

H2S SCAVENGER FIELD TRIALS

DESCRIPTION OF THE PROJECT

Customer: CLIENT2

Field: XX Field

Production Rate: 1380 bopd total

Water Cut: 0% on 25-27.04.2017

H2S Amount: 43,1 ppm

Current H2S Scavenger Dosage Rate: 20-25L/d for 1380 bopd = 92-114 ppm

Specific Gravity: 0,8397 (outlet of the separator)

API: 36

Field Treatment Method: Batch treatment – applied by circulating the produced crude oil in production tanks 1 and 2 into loading tanks 3, 4, and 5. Number of circulations and retention times are determined according to the H2S remaining after the chemical treatment or loading times.

Testing Team: TEKKON Petrochemical Services Co. Ltd. Technical Team

Supervising Team: CLIENT2 Production Management

Applied Tests: Sparge Method

AIM OF THE PROJECT

- Determining the H2S Scav. XX product field performance in XX Field production line,

- Determining the highest and lowest dosage rates for minimum and maximum efficiencies,

- Determining H2S Scav. XX performance post circulation in short (immediate loading to tankers after an approximate of 1 hour circulation) and long retention (recirculation and overnight settling during night shift) times,

- Determining the optimum dosage rate for H2S Scav. XX.

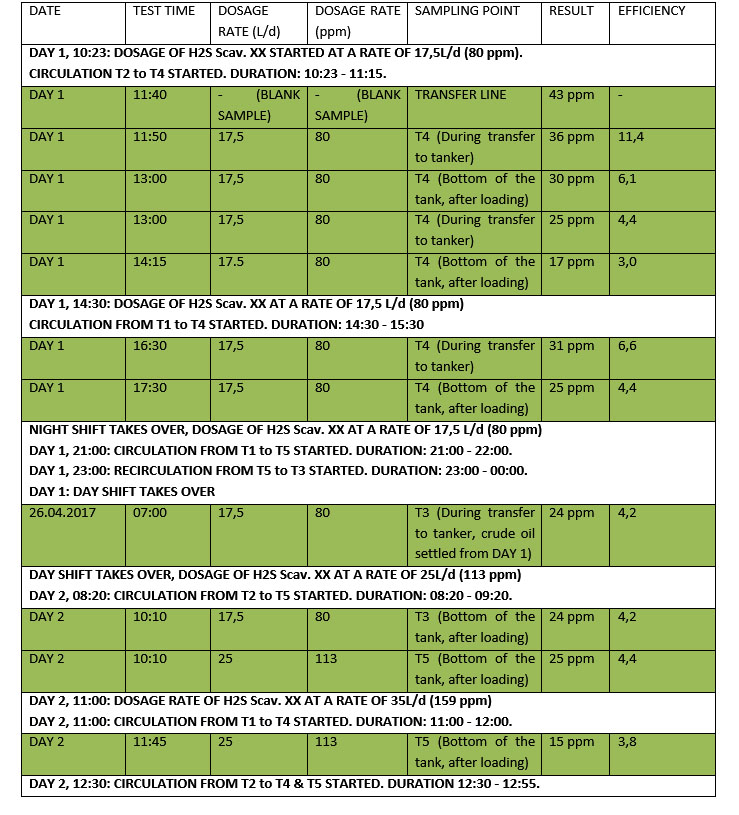

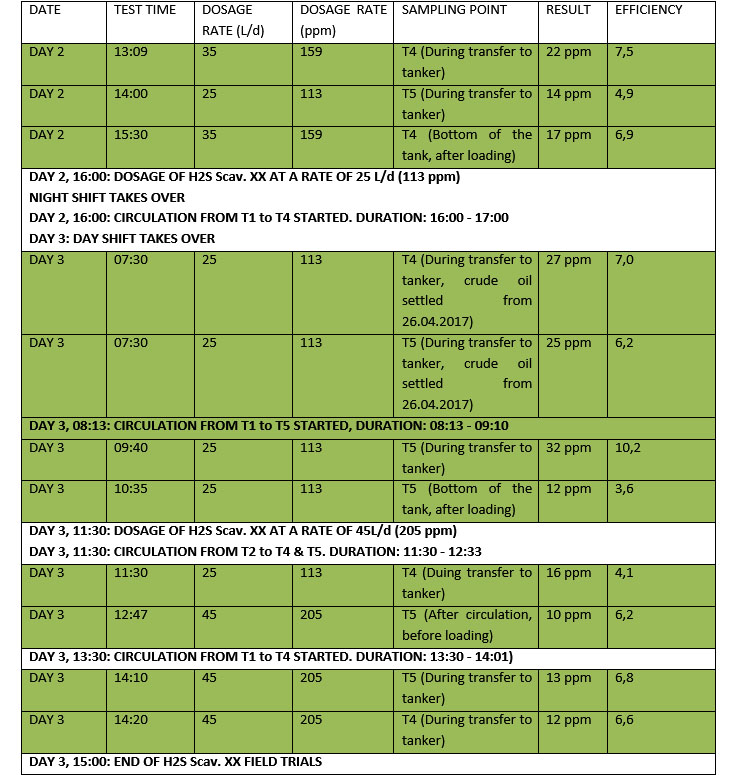

H2S Scav. XX TEST PROGRAM, PARAMETERS, AND RESULTS

CONCLUSIONS & DISCUSSIONS

At the end of the field trials, the following conclusions are reached:

- H2S Scav. XX has shown optimal performance with a dosage rate of 25 L/d. The results obtained has shown immediate results between 20 and 25 ppm, and less than 20 ppm (minimum ppm reached: 14 ppm ) in a short amount of time.

- 35 L/d dosage rate of H2S Scav. XX has shown similar results as 25 L/d injection rate. This similarity is attributed to the nature of applied H2S treatment process, namely batch treatment, which does not give adequate time for proper mixing. This would naturally affect the treatment capabilities of an H2S scavenger, and allows limited observation opportunity for refined dosage adjustment.

- H2S Scav. XX has shown faster performance with a dosage rate of 45 L/d.

- Results obtained with samples collected during loading and after loading has shown that additional retention time greatly helps the H2S treatment.

In conclusion, TEKKON Petrochemical Services Co. Ltd. proposed H2S Scavenger XX product to be used at an optimum dosage rate of 25 L/d for Field operations for an H2S treatment down to approximately 15 ± 2 ppm.